Preventive maintenance is the single most effective way to protect your commercial refrigeration investment, prevent costly product loss, and keep energy costs under control. Since 1979, L & H Services Inc. has provided comprehensive commercial refrigeration maintenance programs throughout Beecher, IL and surrounding communities including Frankfort, Crete, Peotone, and Monee.

Our commercial refrigeration maintenance programs include scheduled service visits that cover condenser coil cleaning, evaporator coil inspection, refrigerant level checks, defrost system testing, door gasket inspection, temperature calibration, electrical connection tightening, and complete system performance evaluation. Each visit is documented for your compliance records.

Regular maintenance extends your refrigeration equipment's lifespan, improves energy efficiency, protects perishable inventory from temperature excursions, and ensures your business stays in compliance with health department requirements year-round.

Call L & H Services Inc. at (708) 231-4800 or contact us online to learn about our commercial refrigeration maintenance programs. We serve businesses throughout Beecher, Peotone, Crete, Frankfort, Monee, and all of Will County.

L & H Services Inc. provides professional commercial refrigeration maintenance programs throughout Beecher, IL and surrounding communities. Regular maintenance keeps your refrigeration reliable and prevents costly product loss.

Commercial refrigeration equipment operates around the clock in demanding environments—walk-in coolers and freezers run 24/7, ice machines cycle constantly, and display cases face repeated door openings and ambient heat loads. Without regular maintenance, these harsh operating conditions accelerate wear, reduce efficiency, and lead to premature failures that can destroy thousands of dollars in perishable inventory.

Dirty condenser coils force compressors to work harder and consume up to 30% more energy, worn door gaskets allow warm air infiltration that drives up operating costs, neglected defrost systems cause ice buildup that restricts airflow, and unchecked refrigerant leaks gradually reduce cooling capacity. Regular professional maintenance addresses all of these issues before they become expensive problems or food safety hazards.

Maintenance customers also receive priority scheduling for any repairs needed, meaning less downtime and less risk of product loss if a problem does occur. Our detailed service reports track your equipment's condition over time, helping you plan for future replacement and maintain compliance documentation for health inspections.

We also provide commercial refrigeration installation and commercial refrigeration repair services. For other commercial maintenance, see our rooftop unit maintenance and cooking equipment maintenance pages.

Protect your refrigeration investment in Beecher. L & H Services Inc. offers maintenance programs that prevent breakdowns, protect inventory, and reduce energy costs. Contact us now to get started.

45+ Years Experience

Licensed & Insured

All Brands Serviced

Flexible Scheduling

Regular maintenance catches minor issues before they cause major failures that can destroy perishable inventory. Our technicians identify worn components, low refrigerant, dirty coils, failing defrost systems, and worn door gaskets during scheduled visits—preventing the emergency breakdowns that result in product loss and costly after-hours repairs.

Breakdown Prevention Benefits:

Well-maintained refrigeration equipment lasts significantly longer and operates more efficiently than neglected units. Regular maintenance protects your investment and keeps operating costs low while ensuring safe food storage temperatures.

Long-Term Benefits:

Well-maintained commercial refrigeration systems operate at peak efficiency, directly reducing your energy costs. Refrigeration often accounts for the largest share of a food service business's energy bill, making maintenance savings substantial.

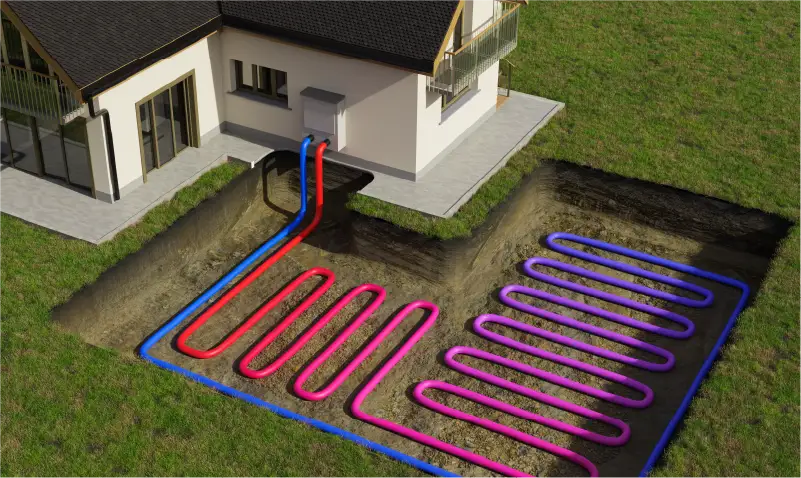

Switch to clean, efficient geothermal heating and cooling. Rebates and incentives are available to help offset your new system's cost.

Rebates, incentives & lower bills.

Geothermal is the cleanest way to heat & cool.

Quiet, reliable performance.

Get answers to your refrigeration maintenance questions

Most commercial refrigeration equipment should be professionally maintained at least quarterly. Walk-in coolers and freezers benefit from service every three months, while ice machines typically need descaling every six months. Equipment in high-heat or grease-laden environments like restaurant kitchens may need monthly condenser coil cleaning. We'll recommend the right schedule based on your specific equipment and operating conditions.

Our comprehensive maintenance visits include condenser and evaporator coil cleaning, refrigerant level checks, defrost system testing, door gasket inspection, temperature calibration, compressor performance testing, electrical connection inspection and tightening, drain line clearing, safety control verification, and a complete system performance evaluation. We provide a detailed service report after each visit for your compliance records.

Maintenance program costs depend on the number and type of equipment, required service frequency, and any additional services needed. A single walk-in cooler costs less to maintain than a full restaurant with multiple coolers, freezers, and ice machines. We provide customized quotes based on your specific equipment inventory. The investment typically pays for itself through energy savings and prevented product loss.

Regular maintenance provides multiple benefits: reduced energy consumption (dirty coils can increase energy use by 30%), extended equipment lifespan, fewer emergency breakdowns, protection of perishable inventory from temperature excursions, compliance documentation for health inspections, preserved manufacturer warranty coverage, and priority scheduling when repairs are needed. Most businesses find the maintenance program pays for itself many times over.

Absolutely. We understand that refrigeration maintenance needs to work around your business operations. We can schedule service during early mornings, evenings, or slower business periods to minimize disruption. For restaurants, we often schedule visits before opening or between lunch and dinner service. Our goal is to keep your equipment running without interfering with your daily operations.

Yes, significantly. Health departments require that commercial refrigeration equipment maintain safe temperatures for food storage. Our maintenance program includes temperature calibration, monitoring verification, and detailed service documentation that demonstrates your equipment is being professionally maintained. This documentation is valuable during health inspections and provides a record of due diligence for food safety compliance.

Most ice machines should be professionally descaled every six months, though this can vary based on water quality in your area. Hard water areas may require more frequent descaling—as often as every three to four months. Descaling removes mineral buildup that reduces ice production, affects ice quality, and can harbor bacteria. We also clean and sanitize the ice bin, check water filters, and inspect all components during ice machine maintenance visits.

The most critical walk-in cooler maintenance tasks are condenser coil cleaning, door gasket inspection, defrost system verification, and refrigerant level checks. Dirty condenser coils are the number one cause of compressor failure and wasted energy. Worn door gaskets allow warm, humid air to enter, causing ice buildup and forcing the system to work harder. A malfunctioning defrost system leads to ice-blocked evaporator coils and temperature problems. Our maintenance program covers all of these critical areas.

Yes, we maintain all brands and types of commercial refrigeration equipment regardless of who installed them. We service walk-in coolers, walk-in freezers, reach-in refrigerators, display cases, ice machines, and prep tables from all major manufacturers. Many businesses switch their maintenance to us after being dissatisfied with another provider. We'll assess your equipment and develop a maintenance program tailored to your specific units.

Yes, substantially. Well-maintained commercial refrigeration equipment can last 15-20+ years, while neglected units often fail in 8-12 years. The compressor is the most expensive component, and regular maintenance—particularly keeping coils clean and refrigerant levels correct—dramatically reduces compressor stress and extends its life. Given the high cost of commercial refrigeration equipment, regular maintenance is one of the best investments a business can make.

Start a preventive maintenance program for your business in Beecher, IL. Prevent breakdowns, protect inventory, and reduce energy costs.

Flexible Scheduling • All Brands • Priority Repair for Members

Don't wait for a breakdown to start maintaining your commercial refrigeration equipment. L & H Services Inc. has been providing professional commercial refrigeration maintenance since 1979, helping businesses throughout Beecher, IL and surrounding communities keep their coolers, freezers, and ice machines reliable and efficient.

Our maintenance programs are customized to your specific equipment, operating conditions, and business needs. Whether you have a single walk-in cooler or a full commercial kitchen with multiple refrigeration systems, we develop a program that keeps everything running at peak performance.

The cost of a maintenance program is a fraction of what emergency repairs, product loss, and premature equipment replacement cost. It's one of the smartest investments a food service business can make.

Call L & H Services Inc. at (708) 231-4800 or contact us online to learn about our commercial refrigeration maintenance programs throughout Beecher, Peotone, Crete, Frankfort, Monee, and all of Will County.

Ask about our multi-unit and multi-system discounts. When your business depends on reliable refrigeration, L & H Services Inc. delivers the professional maintenance you need.